Cartonnerie Jean FG: Tél: +33 (0) 5 55 62 96 50 Fax: +33 (0) 5 55 62 96 59 Email: [email protected]

FIBERBOARD

MATERIAL

The Celloderme is a very hard board with high density manufactured by rolling up humid pulp sheets on a solid board machine.

The Celloderme is a not brittle but rigid material. Its folding is easy as well as thermoforming.

| Raw material | Waste papers |

|---|---|

| Inside processing | Glue, resin, starch, colorants |

TECHNICAL DATA

We get with this manufacturing process for "celloderme" higher mechanical specifications than with other boards

So average rupture lenght can reach 4500 kpa in 1mm thickness for high qualities.

| Grammage | 900 up to 5000gr/m² |

|---|---|

| Density | 0.9 up to 1.1 |

| Burst index | 2 up to 4 |

After treatment "Celloderme" can offer perfect resistance to humidity.

After 1h water submersion:

| Treatment | % Water absorption |

|---|---|

| Usual | 24% |

| Special | 3 up to 5% |

MAIN APPLICATIONS

| Shoe industry | Shankboard for insole, pattern board |

|---|---|

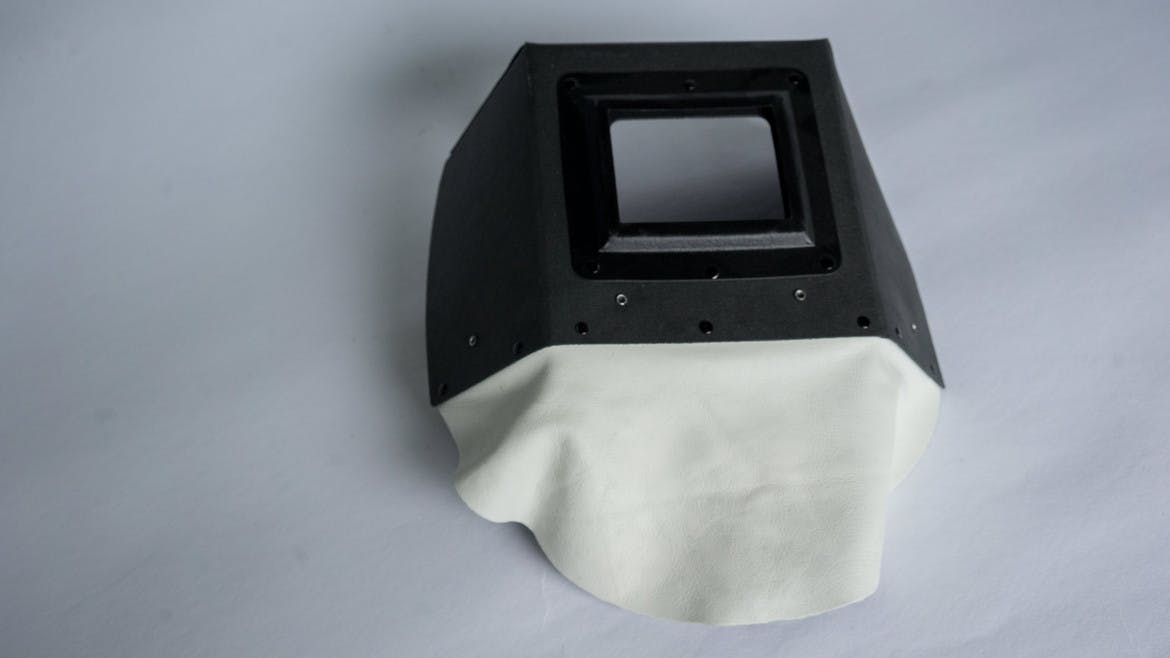

| Automobile industry | Interior tissu, seat trim, eyes welding protector |

| Furniture | Bed Divans, sofas, armchairs |

| Luggage industry | Pattern board, reinforcement |

| Filing industy | Folders, filing cabinets, rececord boxes |

| Industrial packaging | Interplated sheets bottoms for fiber drums |

| Textile | Boards for trimmer |